Supporting precision microsurgery for safer, faster and more effective surgeries.

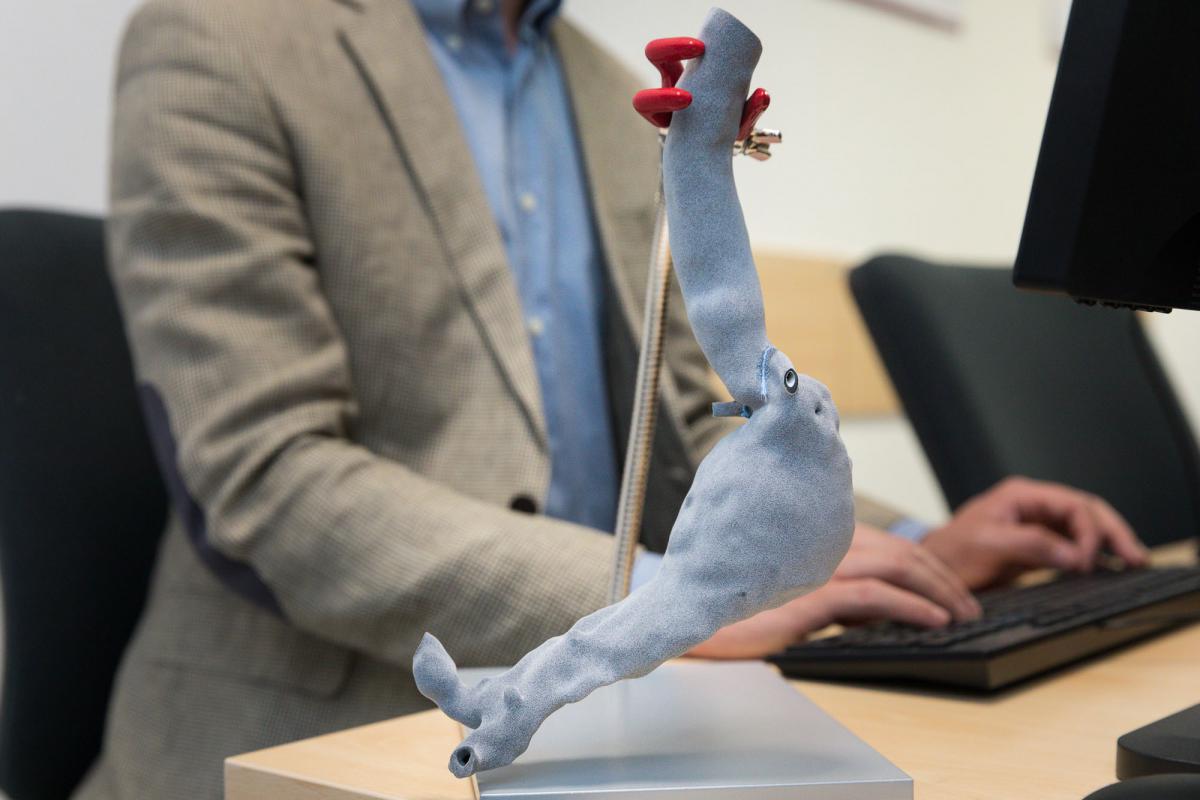

The aorta model is faithful in size and detail to the original of a patient slated for urgent surgery.

Each patient presents a unique clinical situation and anatomy, so the 3D model of the aorta can help surgeons study the best surgery to be performed before they even operate and choose among several possible solutions, discarding unnecessary ones.

It was made in 3D in Trentino Sviluppo’s ProM Facility laboratory in Polo Meccatronica at the request of Ultrasound Lab Trento (ULTRa) of the University of Trento at the Department of Engineering and Information Science, based on the indications and CT data provided by the vascular surgery operating unit of Santa Chiara Hospital in Trento.

What is special about this 3-D aorta made by ProM Facility? The material used is radio-opaque.

ProM Facility engineers processed the 3D model by isolating it from the complete anatomical model of the rib cage. The reworking was done using state-of-the-art software that allows complete control over the produced model and a faithful reconstruction of the internal and external anatomy of the aorta. The 1:1 scale model may also be useful for training activities of new physicians.