From wood industry waste to new sustainable objects

ProM Facility hosted SolidWorld GROUP and its business unit SolidManufacturing to present Forust, the 3D printer that produces components and design objects from wood powder, in full application of the circular economy logic. An event dedicated to all those who wish to explore technological innovations in the field of 3D design and 3D printing applied to the world of wood.

On 6 February, Trentino Sviluppo’s Meeting Room brought together industry experts, designers, architects, technologists and managers interested in discovering how these technologies are redefining the design and production of wooden objects, opening the way to new creative frontiers and industrial applications.

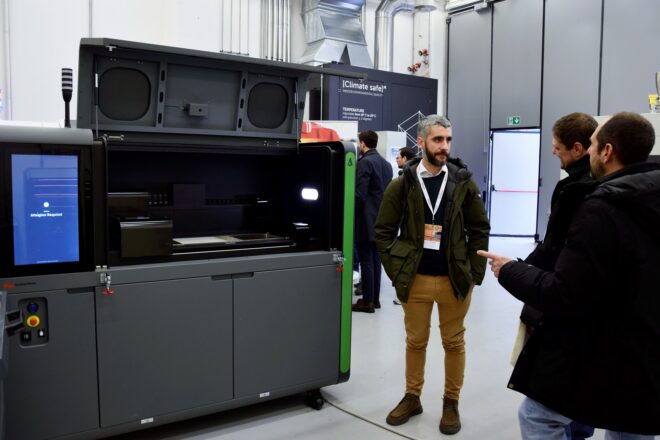

SolidWorld GROUP, operating in the field of digital 3D printing and additive manufacturing technologies, has started the distribution in Italy of the Forust 3D printer, manufactured by the US company Desktop Metal, and the first in the world capable of using wood powder.

During the event, SolidWorld GROUP presented all the innovative projects of the 3D world, illustrating a wide range of integrated solutions for additive manufacturing and the potential of 3D printing in the wood sector. Participants were able to visit the Trentino Sviluppo mechatronic prototyping centre, where the only Forust model in Europe is present and in use, to find out what industrial research activities are underway and the results of the first prototyping of components.

Wood and additive manufacturing: sustainable design and 3D printing

From the combination of two by-products of the wood industry, namely lignin and sawdust, Desktop Metal’s Forust printer can produce isotropic, sustainable wood parts from waste materials derived from trees used, for example, for the construction of houses and furniture components.

The materials that can be used with Forust are:

- sawdust from furniture manufacturing

- binders in aqueous solution

- binders with brown pigment for creating the grain

Any unused sawdust, which is captured during printing or dedusting, can be reused in subsequent constructions.

3D-printed products with Forust are sustainable because they are generated from an environmentally friendly supply chain:

- raw material consumption is reduced

- logistics are optimised

- flexibility and customisation are increased

Binder Jetting technology for wood 3D printing

The Forust process utilises the Binder Jetting technology already developed by Desktop Metal for metal and sand printing, making it the ideal system for the batch production of small to medium-sized wooden parts with complex geometries.

The benefits of using this technology are:

- high productivity 3D printing

- product customisation

- freedom of design and realisation of complex geometries

- simplification of the production cycle

The application areas of wood 3D printing with Forust

Parts moulded with the Forust process can be finished to imitate a wide variety of wood species, with or without wood grain, while still providing a neutral aesthetic.

One of the most important areas of use is the automotive industry, where the 3D printer can make wooden car interior parts with sustainable finishes and materials, rare and exotic grains.

The printer makes it possible to produce objects or components for the consumer, interior design, furniture and musical instrument sectors, allowing designers unprecedented freedom to explore new geometries and applications.

Through Desktop Metal’s ‘Shop System Forust Edition’, the system is fully digitised. The SolidWorld Group’s proprietary software allows both the design of the parts to be printed and the management of the additive manufacturing process, giving users the freedom to create the part and manufacture it according to their own requirements, including architectural elements, using advanced CAD tools and generative design.

Finally, with SolidWorld GROUP’s SWOOD technology the 3D design solutions for woodworking optimise the design and production process.